Use Temperature and Iocation of Refractory Bricks

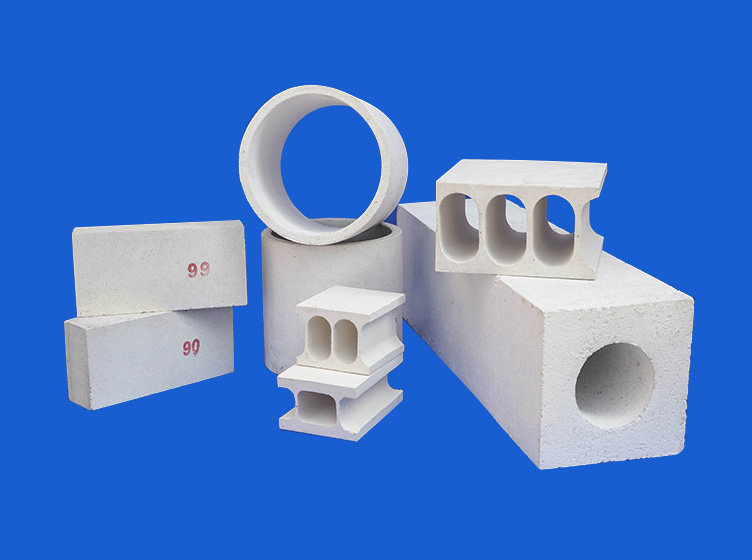

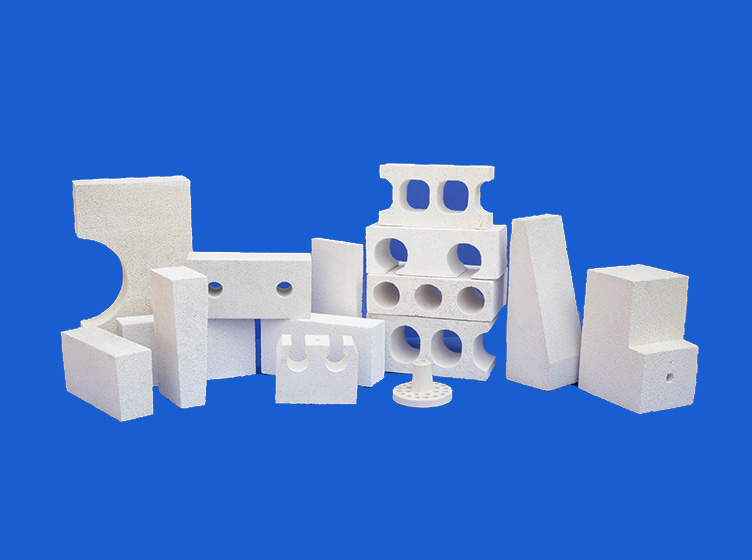

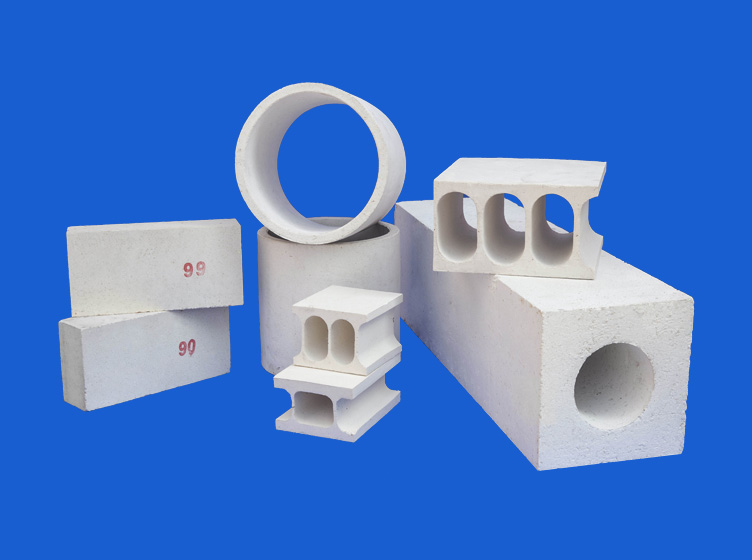

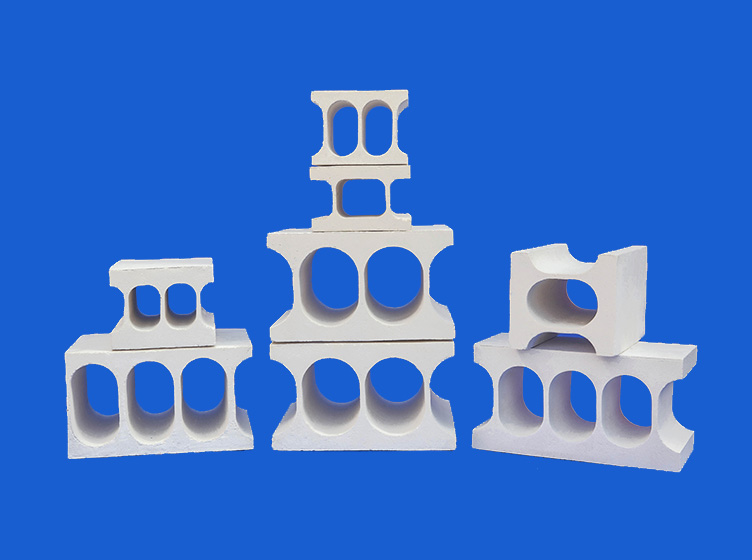

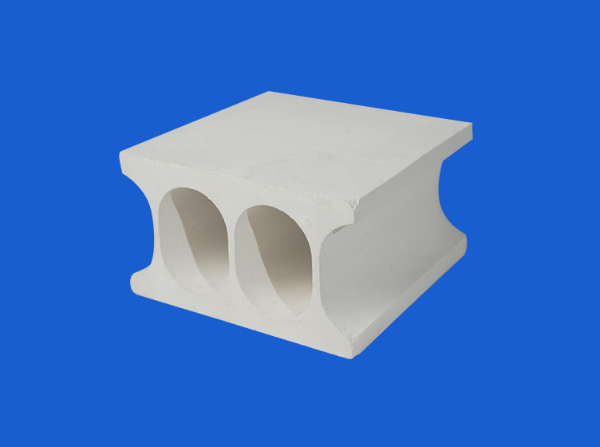

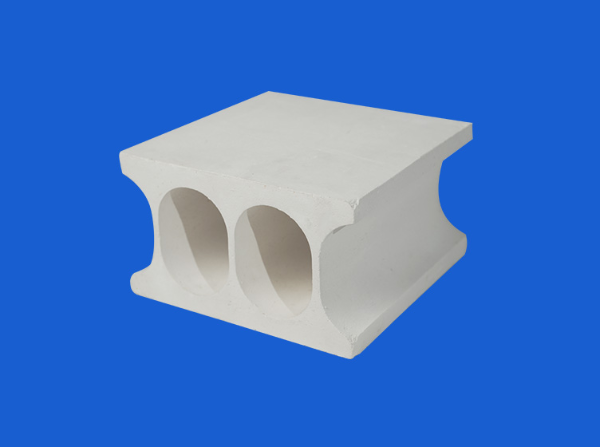

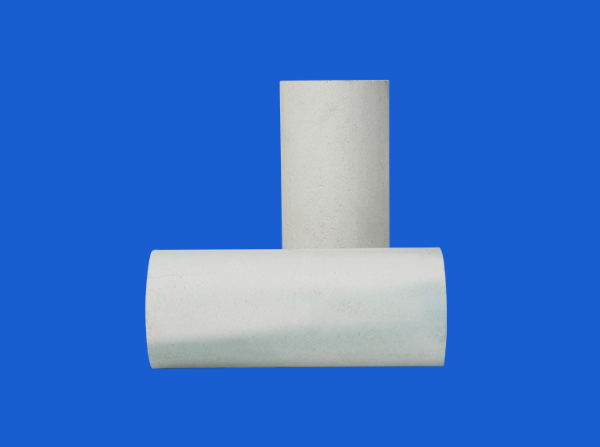

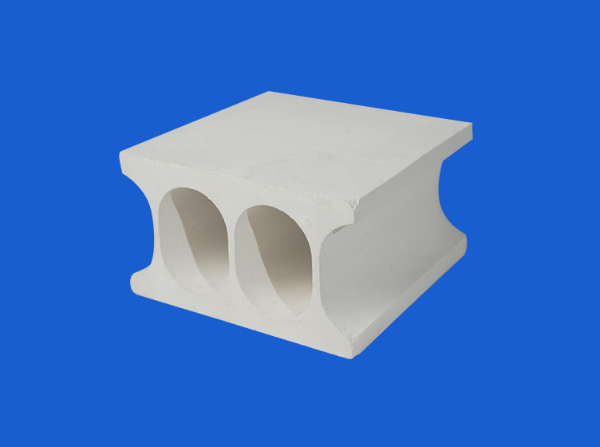

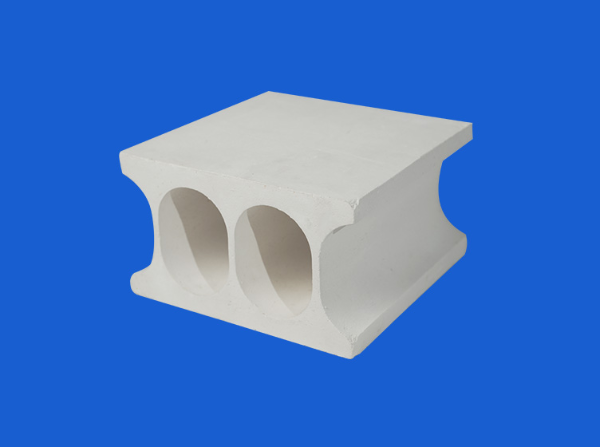

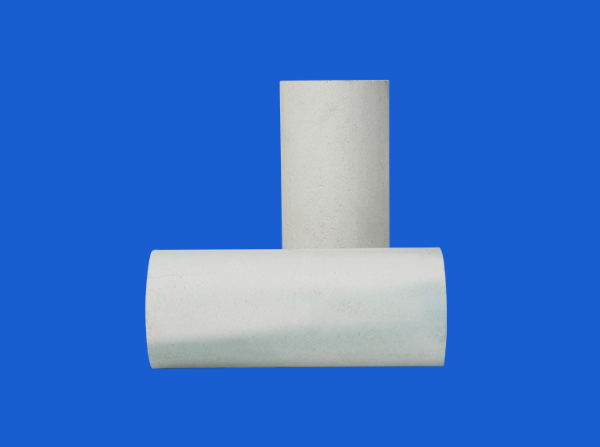

As a shaped refractory material, refractory bricks have diversified products due to different parameters and scope of use.

Refractory bricks have high strength, simple construction, wide range of uses, and easy material selection. They are suitable for the construction of various industrial furnaces and kilns. Their uses and operating temperatures are different. The following points are summarized from many years of experience in the industry. I hope they can help Everyone helps.

1.The physical and chemical indicators, dimensional allowable deviations and cross-section cracks of the ordinary refractory clay bricks should comply with the specifications. Ordinary refractory clay bricks are used as refractory masonry in general furnaces. The operating temperature of lining materials, furnace walls, furnace bottoms, flues, etc. is below 1250°C. The combustion chamber part is allowed to be used above 1400℃.

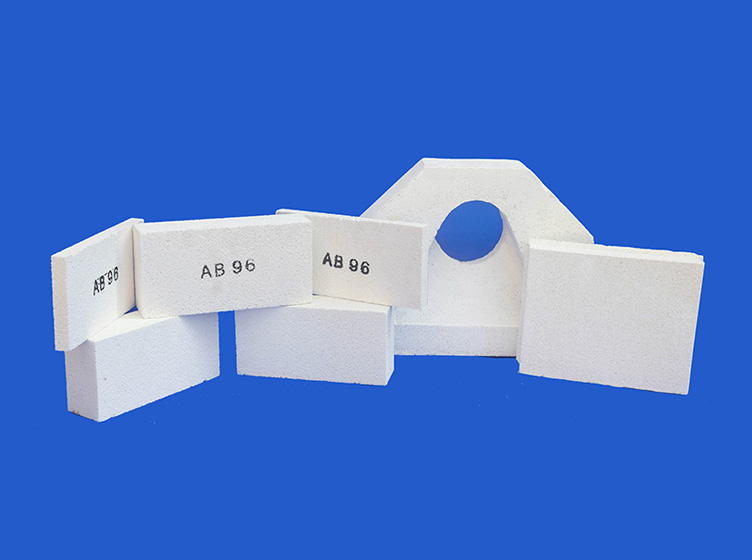

2.The physical and chemical indicators, product dimensions, allowable deviations, etc. of high alumina bricks should comply with the specifications. High alumina bricks are used in masonry, burner bricks and masonry with special requirements in areas with high temperature resistance and wear resistance in general furnaces or in masonry with heavy loads. The dome in the high-temperature area of the combustion chamber is allowed to use a temperature of 1300 to 1650°C.

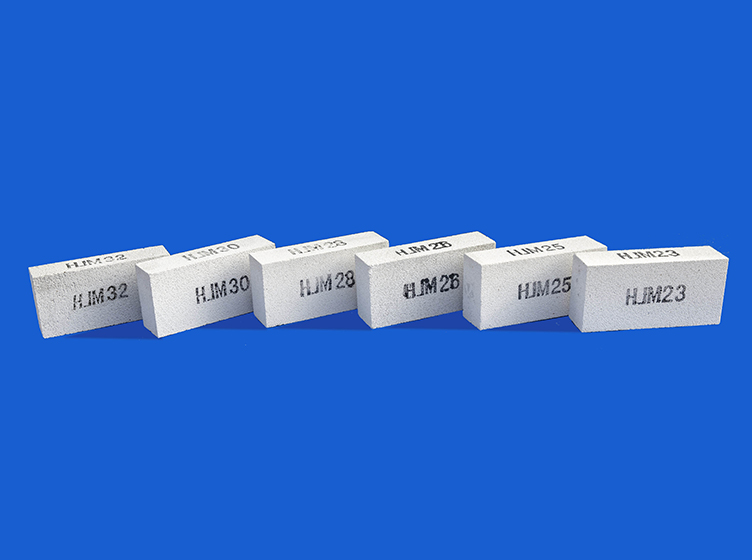

3. The physical and chemical indicators of lightweight clay bricks, the allowable deviation of product dimensions, and the cross-sectional requirements of appearance products should comply with the specifications. Lightweight refractory clay bricks are used as kiln linings that are not corroded by high-temperature slag and corrosive gases. Depending on the capacity, the operating temperature is between 1150 and 1400°C.

4. The physical and chemical indicators of lightweight high-alumina bricks and the allowable deviation of external dimensions should comply with the specifications. It is used for heat-resistant linings with working temperatures below 1350°C. It can also be used for masonry that is not corroded and eroded by high-temperature molten materials and can be in direct contact with flames.

5. General corundum bricks are suitable for fire surface linings of heavy oil gasifiers with working pressures below 3MPa, important parts of salty wastewater incinerator linings, and radiant burner bricks working at high temperatures. Generally, the service temperature of corundum bricks is below 1600~1670℃.

6. Low silicon fused corundum is suitable for occasions with strong reducing atmosphere, high hydrogen content and high temperature water vapor. Such as large-scale ammonia synthesis equipment, the gas collecting pipe lining of the first-stage reformer, the brick lining of the second-stage reformer, and the high-temperature furnace lining. The physical and chemical indicators and dimensional allowable deviations of low silicon fused corundum bricks should comply with the specifications. The operating temperature of low silicon fused corundum is below 1600℃~1670℃.

7. Lightweight alumina products (such as lightweight corundum bricks) are used as heat-resistant and insulating linings in high-temperature furnaces. Linings corroded by high-temperature and high-pressure water vapor are generally used in non-fire surface linings. The use temperature of alumina products is below 1400°C.

8. Silicon carbide refractory bricks have good thermal conductivity, good thermal stability, can resist reducing atmospheres, and have high strength. They are often used as heat-resistant and wear-resistant linings, and need to have good thermal stability, thermal conductivity and resistance to reduction. In the case of sexual atmosphere, the use temperature of silicon carbide refractory products is below 1400~1600℃.

Refractory bricks have high strength, simple construction, wide range of uses, and easy material selection. They are suitable for the construction of various industrial furnaces and kilns. Their uses and operating temperatures are different. The following points are summarized from many years of experience in the industry. I hope they can help Everyone helps.

1.The physical and chemical indicators, dimensional allowable deviations and cross-section cracks of the ordinary refractory clay bricks should comply with the specifications. Ordinary refractory clay bricks are used as refractory masonry in general furnaces. The operating temperature of lining materials, furnace walls, furnace bottoms, flues, etc. is below 1250°C. The combustion chamber part is allowed to be used above 1400℃.

2.The physical and chemical indicators, product dimensions, allowable deviations, etc. of high alumina bricks should comply with the specifications. High alumina bricks are used in masonry, burner bricks and masonry with special requirements in areas with high temperature resistance and wear resistance in general furnaces or in masonry with heavy loads. The dome in the high-temperature area of the combustion chamber is allowed to use a temperature of 1300 to 1650°C.

3. The physical and chemical indicators of lightweight clay bricks, the allowable deviation of product dimensions, and the cross-sectional requirements of appearance products should comply with the specifications. Lightweight refractory clay bricks are used as kiln linings that are not corroded by high-temperature slag and corrosive gases. Depending on the capacity, the operating temperature is between 1150 and 1400°C.

4. The physical and chemical indicators of lightweight high-alumina bricks and the allowable deviation of external dimensions should comply with the specifications. It is used for heat-resistant linings with working temperatures below 1350°C. It can also be used for masonry that is not corroded and eroded by high-temperature molten materials and can be in direct contact with flames.

5. General corundum bricks are suitable for fire surface linings of heavy oil gasifiers with working pressures below 3MPa, important parts of salty wastewater incinerator linings, and radiant burner bricks working at high temperatures. Generally, the service temperature of corundum bricks is below 1600~1670℃.

6. Low silicon fused corundum is suitable for occasions with strong reducing atmosphere, high hydrogen content and high temperature water vapor. Such as large-scale ammonia synthesis equipment, the gas collecting pipe lining of the first-stage reformer, the brick lining of the second-stage reformer, and the high-temperature furnace lining. The physical and chemical indicators and dimensional allowable deviations of low silicon fused corundum bricks should comply with the specifications. The operating temperature of low silicon fused corundum is below 1600℃~1670℃.

7. Lightweight alumina products (such as lightweight corundum bricks) are used as heat-resistant and insulating linings in high-temperature furnaces. Linings corroded by high-temperature and high-pressure water vapor are generally used in non-fire surface linings. The use temperature of alumina products is below 1400°C.

8. Silicon carbide refractory bricks have good thermal conductivity, good thermal stability, can resist reducing atmospheres, and have high strength. They are often used as heat-resistant and wear-resistant linings, and need to have good thermal stability, thermal conductivity and resistance to reduction. In the case of sexual atmosphere, the use temperature of silicon carbide refractory products is below 1400~1600℃.