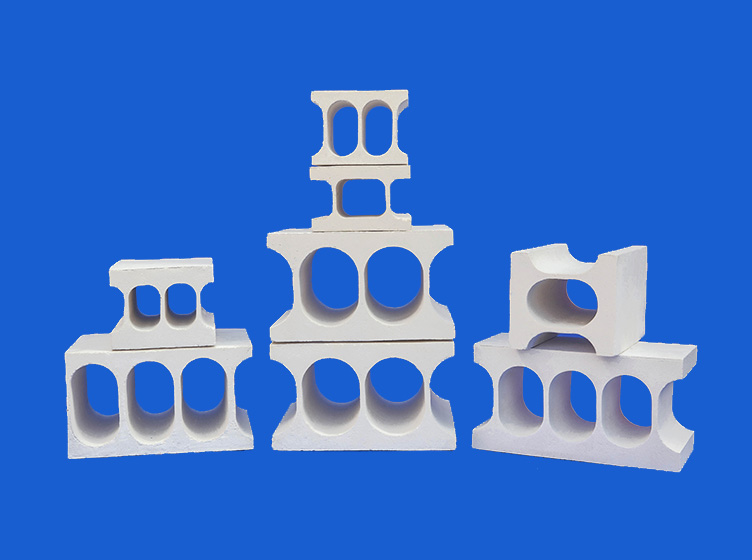

Importance of Anti Carburizing Refractory Brick

In the field of industrial manufacturing,

Anti Carburizing Refractory Brick has become increasingly important and has become an indispensable key element in the production process of various major industries. Its unique fire resistance and anti-carbonization properties make it play a vital role in high-temperature, high-carbon environments, protecting various equipment from carbonization and corrosion.

Anti Carburizing Refractory Brick's primary attribute is its excellent fire resistance. Thanks to the high-quality refractory raw materials used in the manufacturing process, the bricks are able to maintain their physical and chemical properties under extreme heat conditions and are less susceptible to severe thermal damage. In industrial production, many equipment need to withstand high-temperature environments, such as iron-making furnaces, steel-making furnaces, etc. The fire-resistant properties of Anti Carburizing Refractory Brick can ensure that these equipment can still operate stably at high temperatures without being restricted by refractory materials.

Secondly, the anti-carbonation properties of Anti Carburizing Refractory Brick add value that cannot be ignored in industrial applications. In some production processes, high-temperature environments may cause carbon elements to penetrate into the refractory materials of the equipment, thereby reducing the performance and life of the equipment. Anti Carburizing Refractory Brick effectively extends the service life of equipment and improves the stability of production equipment by preventing the penetration of carbon elements. This is crucial for many industries such as ceramics, metallurgy, and chemicals.

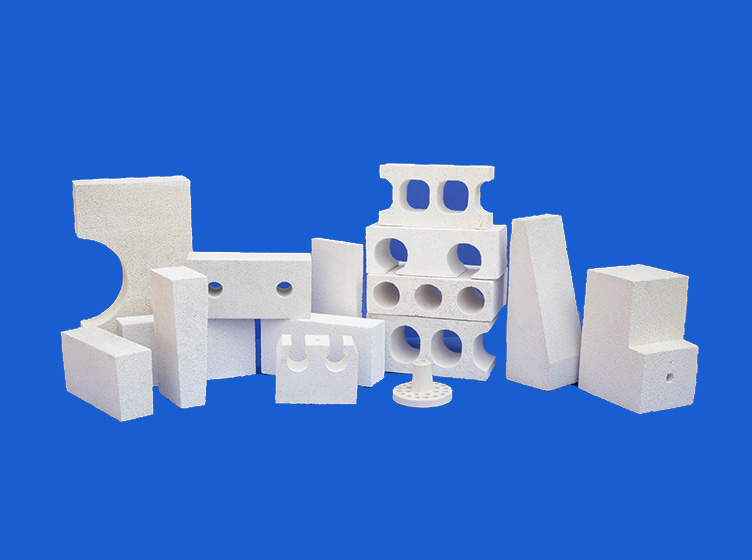

In the steel industry, Anti Carburizing Refractory Brick is particularly widely used. High-temperature and high-carbon environments are inevitable challenges in the steel production process, and this kind of refractory bricks can play a key role in the lining of iron-making furnaces, steel-making furnaces and other equipment, effectively preventing carbon elements from corroding equipment. This not only increases the service life of the equipment, but also reduces the cost of maintenance and replacement of refractory materials, providing strong support for the sustainable development of the steel industry.

In the chemical industry, some production processes also produce carbonized atmospheres in high-temperature environments. Anti Carburizing Refractory Brick is widely used in the lining of reactors, kilns and other equipment to ensure long-term stable operation of equipment in harsh environments. This is crucial to the safety and efficiency of chemical production. The application of Anti Carburizing Refractory Brick provides reliable fire resistance protection for the chemical industry.

In the glass industry, Anti Carburizing Refractory Brick also plays a key role. Glass melting furnaces operate at extremely high temperatures, and the atmosphere in the furnace may cause carbonization of the refractory materials. This refractory brick is widely used in the glass industry to protect the lining of melting furnaces and ensure the stability and efficiency of the glass production process. Its fire-resistant properties and anti-carbonation properties make it an indispensable refractory material in the glass industry.

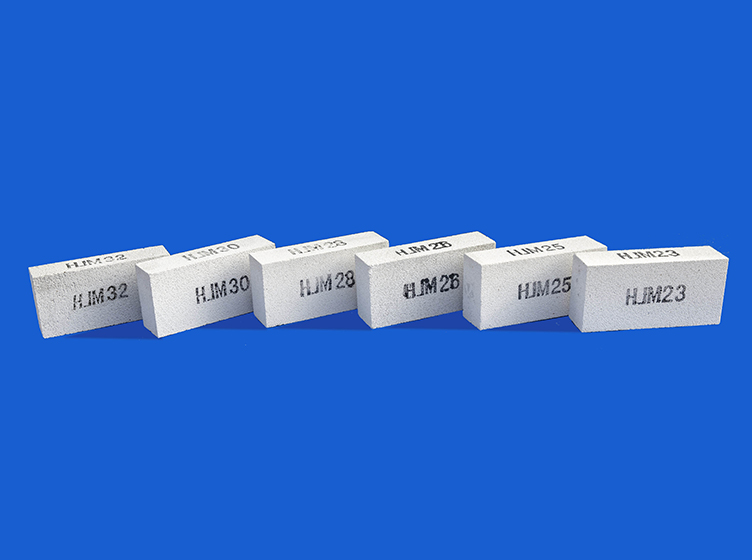

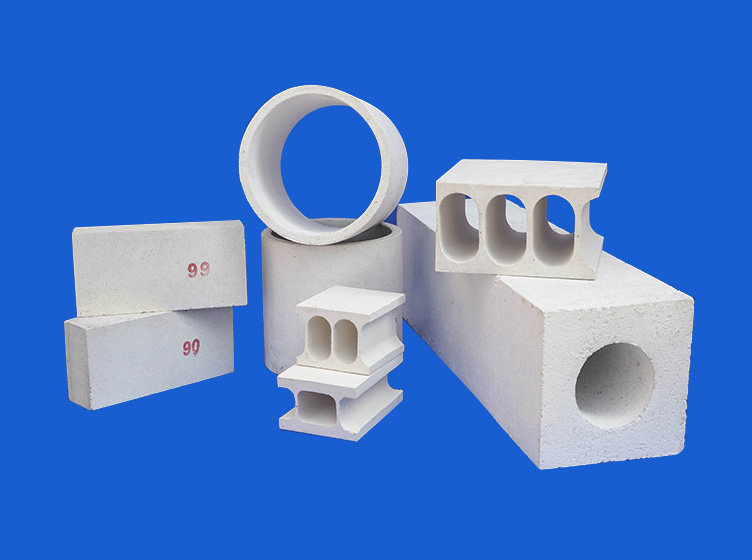

Anti Carburizing Refractory Brick Properties

Anti Carburizing Refractory Brick, as a refractory material widely used in high temperature and high carbonization environments, has many characteristics and provides excellent performance and reliable protection for industrial production.

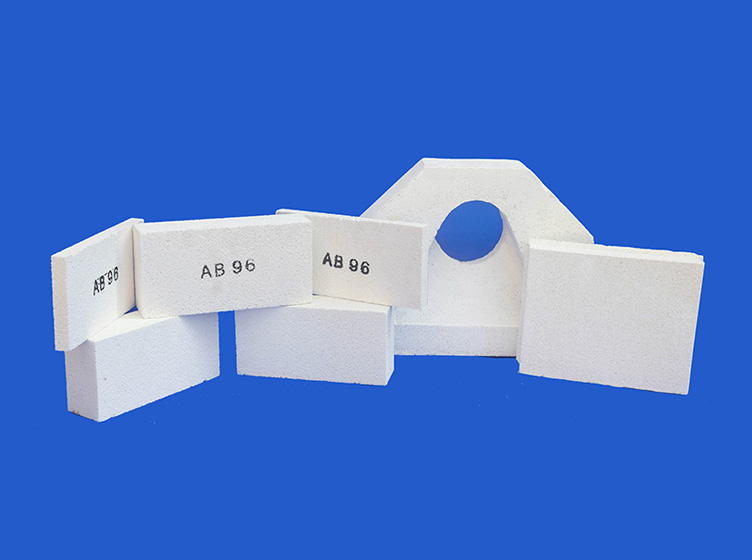

Fire resistance

Due to the high-quality refractory raw materials used in its preparation, this brick is able to maintain the stability of its physical and chemical properties in extreme high-temperature environments. This characteristic makes Anti Carburizing Refractory Brick an ideal choice in high-temperature industrial fields such as steel, chemicals, and glass. It can maintain its performance for a long time in harsh production environments and ensure stable operation of equipment.

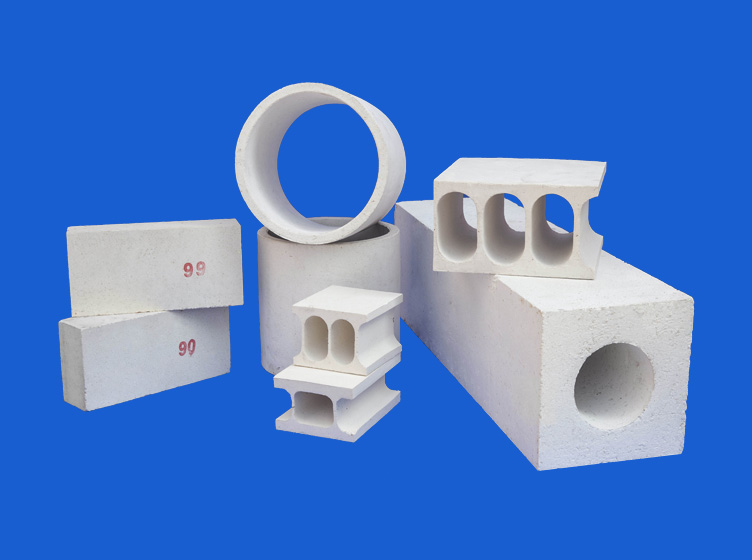

Anti-carbonation properties

In high-temperature and high-carbon environments, some traditional refractory materials are easily corroded by carbon elements, resulting in reduced equipment performance and shortened service life.

Anti Carburizing Brick, through its unique preparation process and material composition, can effectively resist the penetration of carbon elements, thereby extending the service life of the equipment and improving the reliability of the equipment.

Wear resistance

In some high-temperature industrial environments, the materials inside the equipment are often impacted and rubbed by particulate materials, and are prone to wear. Anti Carburizing Refractory Brick excels in this regard. Its wear-resistant properties allow it to withstand the impact of granular materials for a long time, extending the service life of the equipment and reducing the frequency of maintenance and replacement.

chemical stability

In high-temperature industrial production, some corrosive gases and liquids may have adverse effects on the refractory materials of equipment. Anti Carburizing Refractory Brick has been carefully designed in the selection of chemical components and has good chemical stability. It can maintain relatively stable performance in corrosive environments and ensure the normal operation of equipment.

Thermal conductivity

In high-temperature industrial production, uniform temperature distribution is crucial for the normal operation of equipment. Anti Carburizing Refractory Brick, through its excellent thermal conductivity, can help maintain uniform temperature distribution inside the equipment, improve the thermal efficiency of the equipment, and ensure the stability of production.