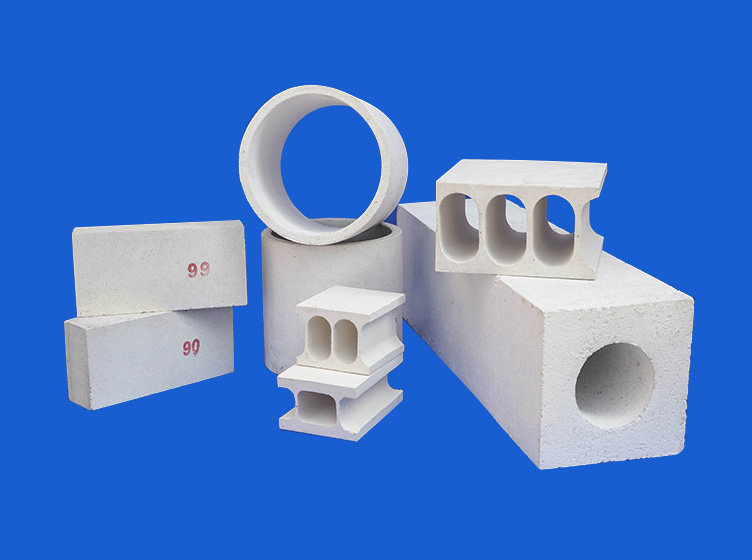

Composition of Heavy High Aluminum Brick

Heavy-duty

high alumina bricks are a refractory material that performs well in high-temperature, high-pressure and heavy-load environments. Its unique composition determines its wide application in various industrial fields.

Alumina (Al2O3)

Alumina is one of the main components of heavy-duty high-alumina bricks, usually accounting for the majority of their total mass. Aluminum oxide is an inorganic compound whose high stability and resistance to high temperatures make it an ideal building block for refractory materials. In high-temperature environments, alumina exhibits excellent heat resistance and can maintain the stability of its physical and chemical properties and is not easy to melt or decompose, allowing heavy-duty high-alumina bricks to maintain structural integrity under extreme conditions.

Aluminum silicate (Al2SiO5)

Aluminum silicate is another key ingredient, and its addition effectively enhances the corrosion resistance of heavy-duty high-alumina bricks. Aluminum silicate forms a strong structure at high temperatures and is resistant to acidic and alkaline environments. This makes heavy-duty high-alumina bricks an ideal choice in areas that require extremely high corrosion resistance, such as the chemical industry. They can resist the erosion of various corrosive atmospheres and extend the service life of equipment.

Highly pure raw materials

In addition to alumina and aluminum silicate, the raw materials used in manufacturing heavy-duty high-alumina bricks must be of high purity. This is to ensure that the chemical composition of the bricks is uniform and to avoid the presence of impurities, thus improving the stability and performance of the product. Highly pure raw materials are a critical part of the manufacturing process and directly affect the quality of the final product.

Other Additives: The Secret Weapon for Tuning Performance

During the manufacturing process, in order to further optimize the performance of heavy-duty high-alumina bricks, some other specific compounds are often added as performance-adjusting additives. These additives may include magnesium oxide, calcium oxide, etc. Their addition can change the characteristics of the brick to a certain extent and make it more suitable for specific industrial needs.

Manufacturing process of Heavy High Aluminum Brick

The manufacturing process of heavy-duty

high alumina bricks is a precise and complex process that combines high-temperature processes, exquisite technology and strict quality control. Together, these key steps ensure the superior performance of the final product, making it the top refractory material in high temperature, high pressure, and heavy load environments.

Raw material preparation: the choice of materials determines quality

The manufacturing of heavy-duty high-alumina bricks begins with the preparation of raw materials. Highly pure aluminum oxide and aluminum silicate are the main ingredients, and the selection of these raw materials is critical to the quality of the final product. Manufacturers need to ensure the purity and uniform distribution of raw materials to avoid impurities in the product that affect performance.

Mixes and Formulation: Precise Chemical Combinations

Mixing and formulating is one of the key manufacturing stages. At this stage, the raw materials are mixed in precise proportions to ensure an even distribution of the various ingredients in the brick. The accuracy of this step directly affects product performance in subsequent process steps.

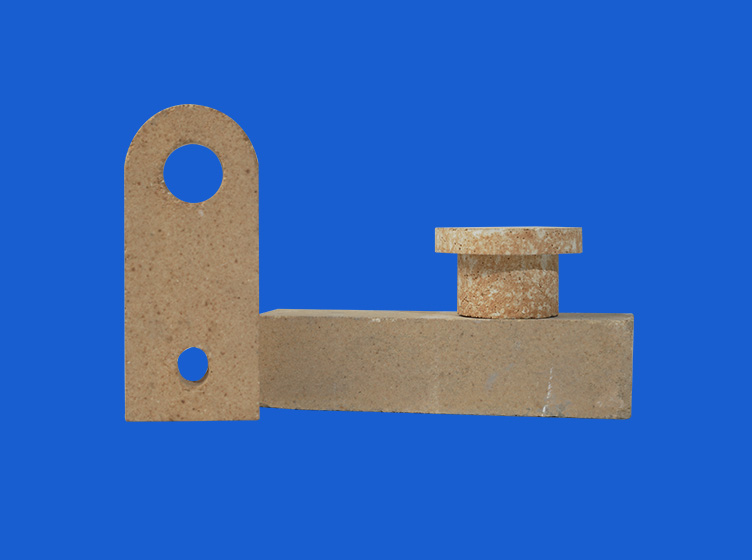

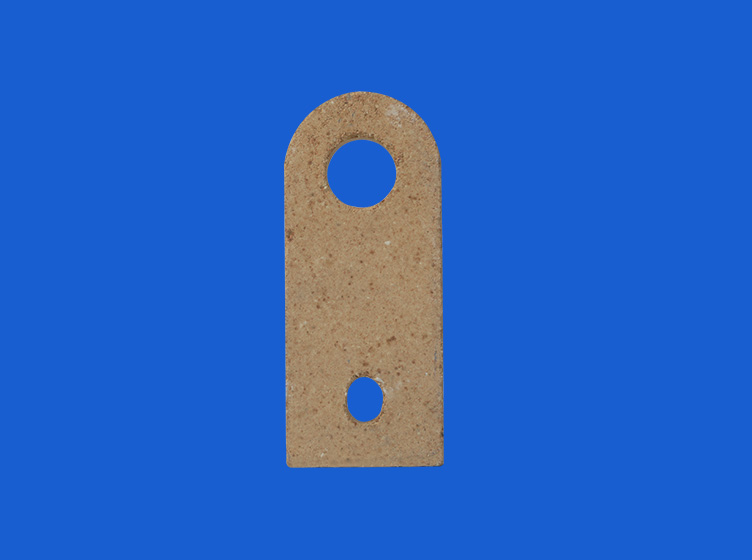

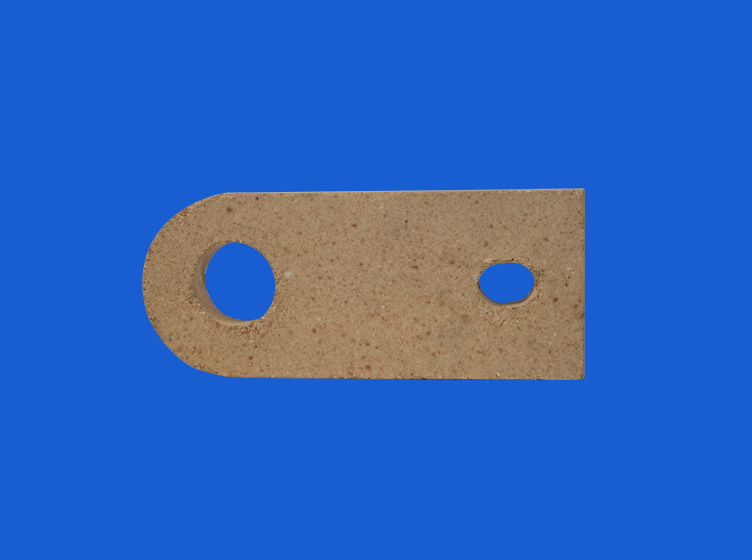

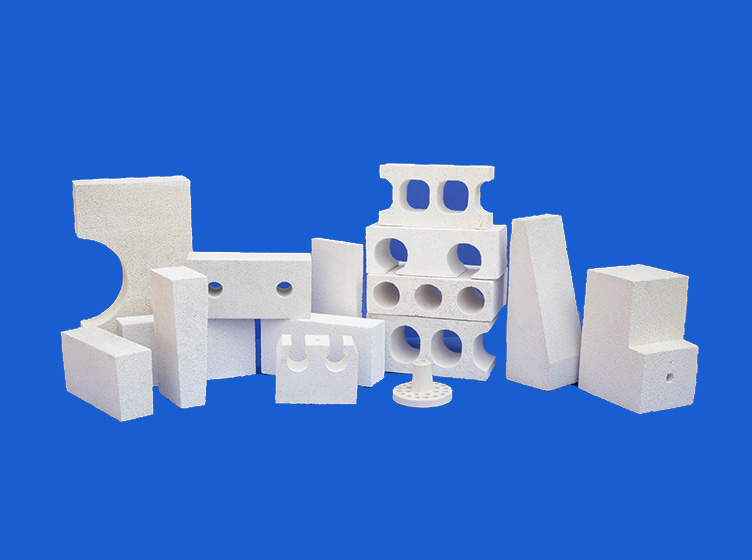

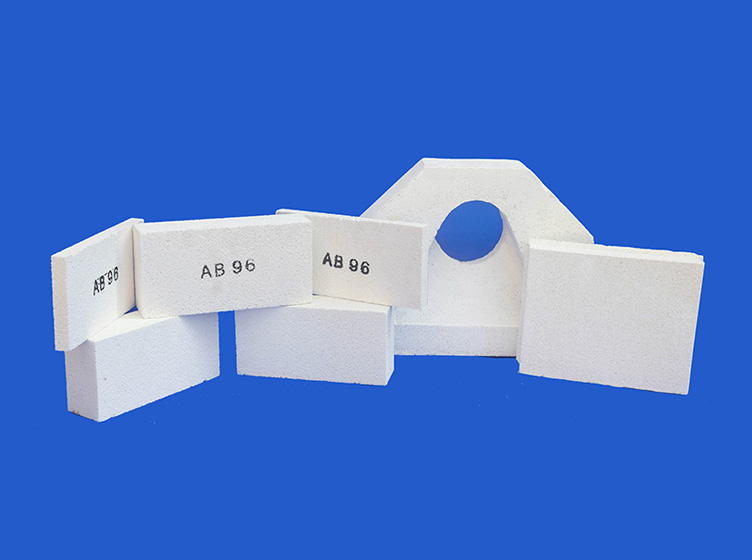

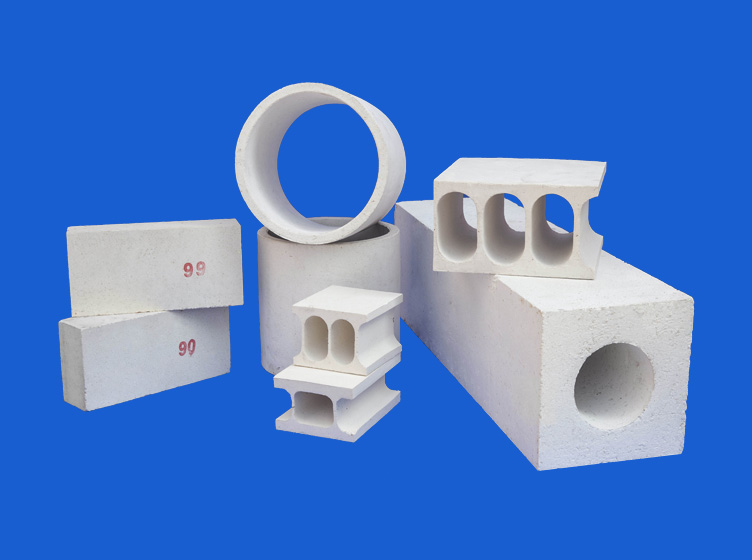

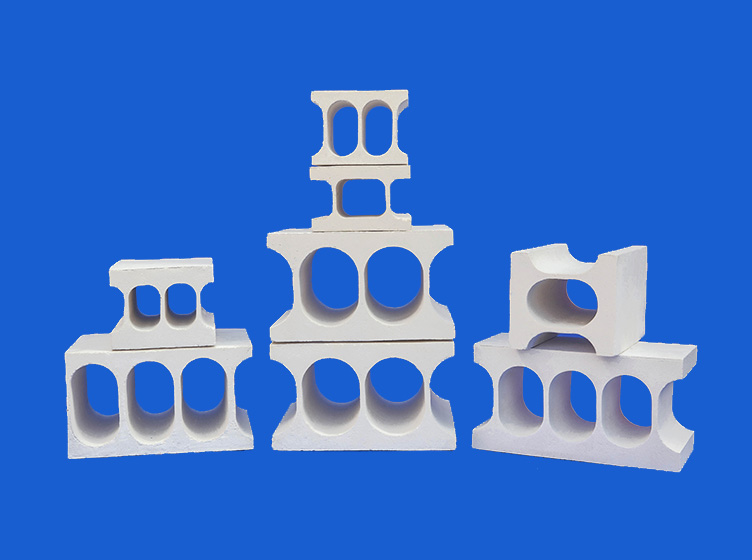

Mold design and molding: shaping of shapes

Once the mixture is prepared, next comes mold design and shaping. Advanced mold design is key to ensuring the final product meets strict specifications. Through precision molds, the mixture is formed into the shape of bricks, which include various specifications and sizes required for heavy-duty high-alumina bricks.

Drying: removing moisture to increase density

The shaped bricks need to go through a drying process. This step is designed to remove moisture from the mix while increasing the density of the bricks. The high-temperature drying process is a time-consuming step and ensures that the bricks can stably maintain their shape during the next step of sintering.

High temperature sintering: forming a dense structure

High-temperature sintering is one of the core steps of the manufacturing process. At high temperatures, the bricks undergo chemical reactions and changes in crystal structure, forming a dense and strong structure. This gives the heavy-duty high-alumina bricks excellent fire resistance and mechanical strength, allowing them to maintain structural integrity under extreme conditions.

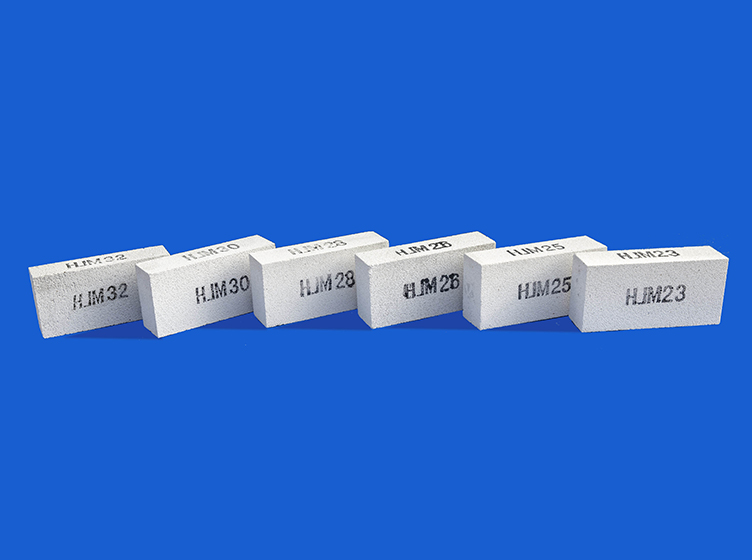

Quality inspection and packaging: ensuring excellent quality

The final stage of the manufacturing process is quality inspection and packaging. Through strict quality inspection procedures, we ensure that each heavy-duty high-alumina brick meets predetermined standards and specifications. Qualified products are packaged and ready to be shipped to customers, providing reliable fire-resistant solutions for high-temperature environments in various industries.