For industrial equipment, how do insulation materials improve equipment efficiency and performance?

Insulation materials play a crucial role in modern industries. They are not just simple thermal insulation materials, but also key factors in improving the efficiency and performance of industrial equipment. By carefully selecting and applying insulation materials, industrial enterprises can achieve more efficient and reliable equipment operation, thereby improving production efficiency, reducing energy consumption, and achieving sustainable development goals.

Heat preservation: Insulation materials can act as a solid thermal barrier, effectively preventing heat transfer inside industrial equipment. By utilizing advanced insulation properties such as low thermal conductivity and high heat resistance, these materials form an insulating shell around key components to prevent heat loss and ensure optimal working temperature. In applications where precise temperature control is critical, such as industrial furnaces, ovens and reactors, such precise control of thermodynamics is essential.

Energy saving: The use of high-performance insulation materials is the cornerstone of energy saving in industrial operations. By suppressing heat dissipation and minimizing heat loss, these materials enable equipment to operate more efficiently, thereby reducing overall energy demand and carbon footprint. As industrial facilities strive to meet stringent sustainability goals and regulatory requirements, the resulting energy savings can translate into both tangible cost reductions and tangible environmental benefits.

Prevention of condensation: In harsh and fluctuating environments with changing temperature and humidity levels, the risk of condensation on the surface of industrial equipment poses a general threat to operational integrity. Insulation materials can act as a powerful defense, preventing water ingress and condensation formation, thereby avoiding corrosion, degradation and microbial growth. By keeping the surface above the dew point temperature, these materials can maintain the reliability, service life and operational flexibility of the equipment, especially in fields such as chemical processing, food production and pharmaceutical manufacturing.

Enhanced safety: The application of insulation materials is crucial to mitigating thermal hazards in industrial environments and protecting personnel from accidental burns or injuries. By encapsulating hot surfaces and confining heat energy within controlled boundaries, these materials create a safer working environment that meets stringent health and safety standards. From high-temperature steam pipes to industrial boilers, the strategic deployment of insulation solutions significantly reduces the risk of workplace accidents, improves employee well-being, and cultivates a safety awareness culture throughout industrial operations.

Noise reduction: In addition to thermal insulation properties, some insulation materials also exhibit excellent acoustic properties, effectively reducing noise emissions generated by industrial equipment during operation. By absorbing sound waves and damping mechanical vibrations, these materials can reduce occupational noise exposure, thereby minimizing the risk of noise-induced hearing loss and improving worker productivity. From heavy machinery in manufacturing plants to HVAC systems in commercial facilities, the use of sound-absorbing and heat-insulating materials helps to create a quieter and more conducive working environment, which is conducive to concentration and overall health.

Equipment protection: Insulation materials protect industrial equipment from various external threats, including water ingress and chemical exposure, mechanical wear and environmental pollutants. By forming a durable, weather-resistant shell around sensitive components, these materials can enhance equipment integrity, extend service life, and minimize downtime due to maintenance or repairs. Whether applied to pipelines in petrochemical refineries or turbine casings in power plants, the powerful protection capabilities of insulation solutions can improve operating reliability and asset life, ensuring uninterrupted productivity and reducing costly disruptions.

Insulation materials play an irreplaceable role in industrial equipment. They can effectively improve the efficiency and performance of equipment, reduce energy consumption, protect equipment safety, and improve the working environment.

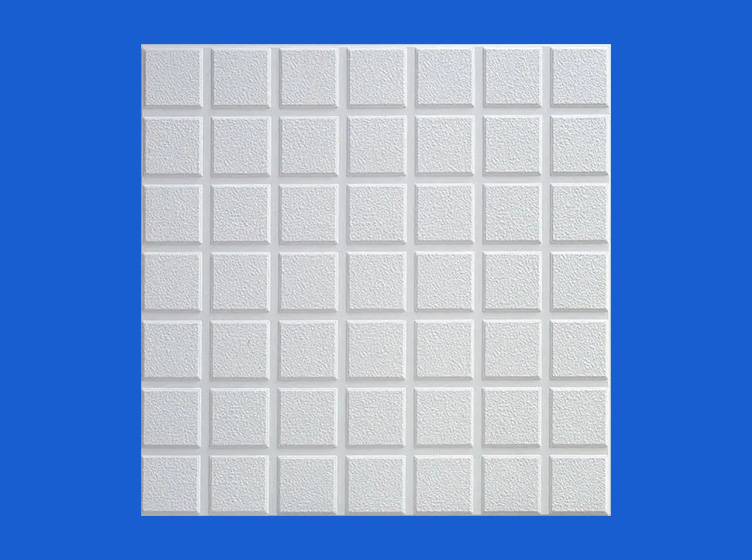

Product Description: Silica calcium board, also known as gypsum composite board, is a type of multivariate material that is generally composed of natural gypsum powder, white cement, glue, and glass fiber. Silicon calcium board has properties such as fire prevention, moisture prevention, sound insulation, and heat insulation.