The application of Insulating Refractory Bricks in the metallurgical industry

The metallurgical industry is representative of high-temperature processes, involving equipment such as blast furnaces, converters, and electric furnaces, all of which need to withstand extremely high temperatures and pressures. In such environments, the application of Insulating Refractory Bricks becomes particularly important. Not only do they provide necessary protection for equipment, ensuring the continuity and stability of production, but they also enhance energy efficiency and production safety.

Within metallurgical equipment, thermal insulation refractory bricks are used as critical lining materials. These devices often operate at temperatures reaching several hundred degrees or even higher. Ordinary materials would quickly degrade at such temperatures, but thermal insulation refractory bricks, due to their special materials and manufacturing processes, can endure such high-temperature environments, ensuring the long-term stable operation of equipment.

Another major advantage of thermal insulation refractory bricks is their ability to effectively reduce heat loss. In the metallurgical production process, if the heat generated by equipment cannot be efficiently utilized, it not only results in energy wastage but also increases production costs. However, the application of thermal insulation refractory bricks ensures the maintenance of high-temperature environments within equipment, reducing heat loss and thereby improving energy efficiency.

High-temperature environments not only damage the lining materials of equipment but also affect the equipment structure itself. Prolonged exposure to high temperatures can cause problems such as structural deformation and strength reduction. The application of thermal insulation refractory bricks can provide an effective thermal barrier for equipment structures, reducing the impact of high temperatures on equipment structures and extending the equipment's service life.

The metallurgical industry is a high-risk sector, where equipment failures, accidents, and other incidents can seriously impact production. However, the application of thermal insulation refractory bricks can to some extent reduce these risks. They can withstand harsh environments such as high temperatures and pressures, ensuring the stable operation of equipment and thus ensuring production safety.

Insulating Refractory Bricks are widely used in the metallurgical industry and are of significant importance in improving equipment lifespan, saving energy, and ensuring production safety. With the continuous development of metallurgical technology, the performance and application scope of thermal insulation refractory bricks will also continue to expand.

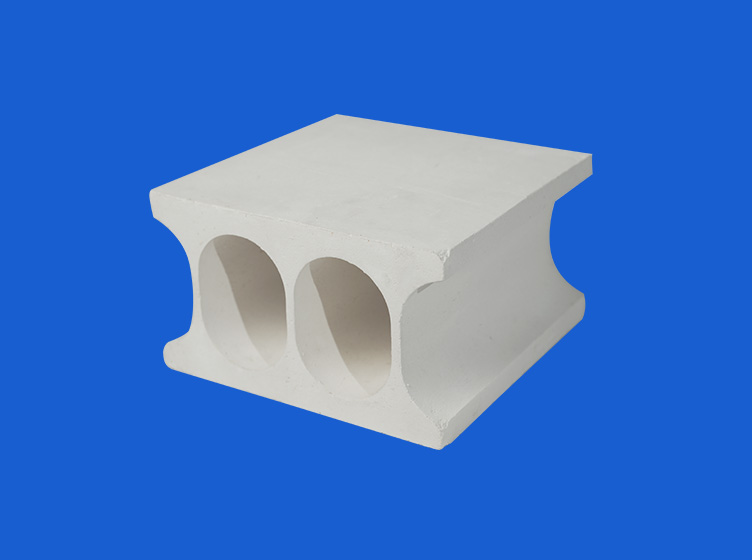

Application: Applied to a variety of high-temperature kilns, such bricks may be manufactured into saggars, guide rails, ejector plates, refractory slabs, brace plates, burn plates, burner blocks and hearths, furnace tubes, and other refractory products.