Material Advantages of Ceramic Fiber Products

Ceramic fiber products are a type of high-performance fiber materials made with ceramics as the main raw material. They are favored in many industrial applications, mainly due to their unique material advantages.

High temperature resistance

Ceramic fiber products are known for their excellent high temperature resistance. This characteristic stems from its main ingredients, which usually use high-purity alumina, aluminum silicate and other ceramic raw materials. These ceramic materials have high melting points and excellent stability, allowing ceramic fiber products to maintain structural integrity and stable performance in extreme high-temperature environments. In high-temperature industrial fields such as aerospace, metallurgy, and petrochemicals, ceramic fiber products are widely used in key links such as heat insulation, smoke insulation, and sound insulation to ensure safe and reliable operation of equipment under extreme conditions.

Corrosion resistance

In addition to their excellent performance in high-temperature environments, ceramic fiber products also exhibit excellent corrosion resistance. This characteristic makes it find wide application in chemical industry, electric power and other fields. Ceramic fiber products can not only resist the erosion of corrosive media such as acids and alkalis, but also maintain high stability. In chemical industry installations, ceramic fiber products can be used to create corrosion-resistant insulation layers to extend the service life of equipment; in the power industry, they can be used as insulation materials for electrical equipment to ensure the reliability of equipment in humid or corrosive environments.

Lightweight design and high strength

Compared with traditional insulation materials, ceramic fiber products have significant advantages in lightweight design and high strength. Its low density can effectively reduce the weight of the overall structure, thereby improving fuel efficiency and reducing transportation burdens in automobiles, aircraft and other fields. At the same time, the high strength characteristics of ceramic fiber products enable them to maintain structural integrity in stressed environments, providing reliable support for various industrial equipment.

Good thermal insulation properties

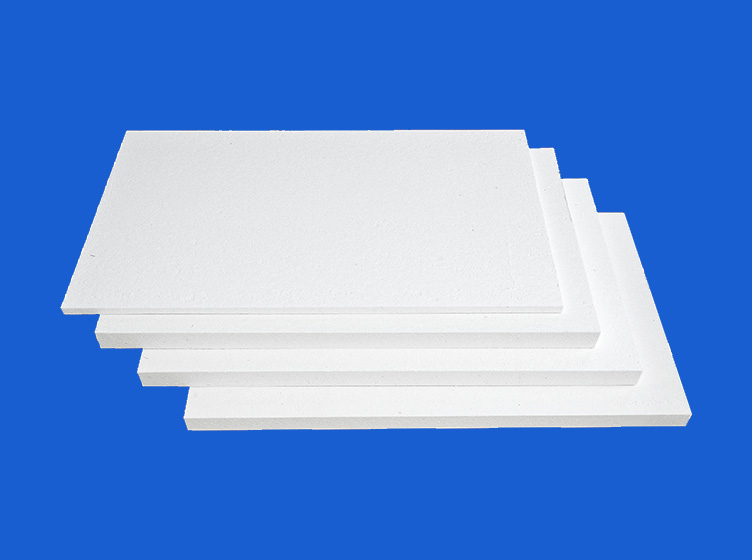

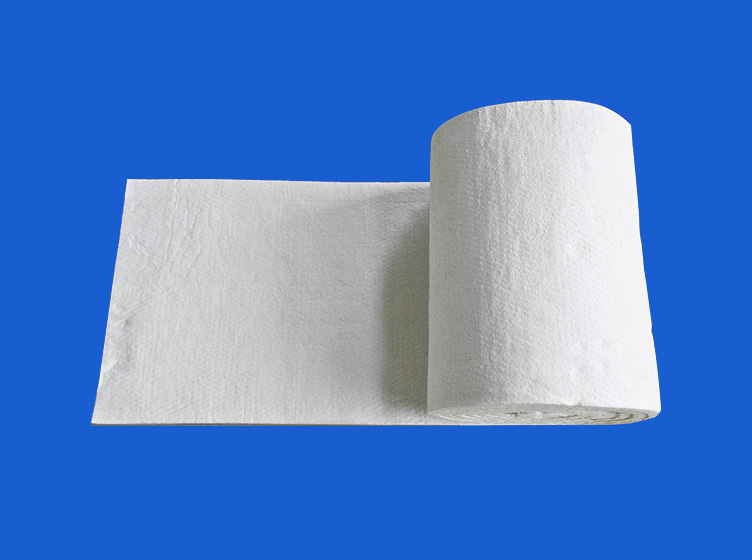

Ceramic fiber products have excellent thermal insulation properties and can effectively prevent heat conduction. This makes it widely used in the manufacture of thermal insulation materials in construction, metallurgy and other fields. In the field of construction, ceramic fiber products are widely used in products such as insulation boards and insulation blankets, which help improve the energy efficiency of buildings and reduce energy waste.

Ease of processing and flexibility

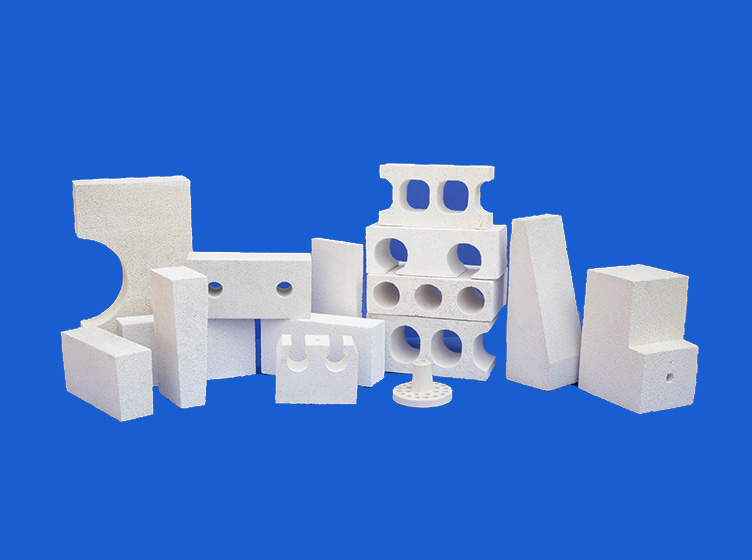

Ceramic fiber products have excellent processing performance and flexibility, and can be cut and bent according to specific needs to adapt to various shapes and structures. This ease of processing has led to the widespread use of ceramic fiber products in the insulation and cladding of complex industrial equipment.

Structural design features of Ceramic Fiber Products

As a type of high-performance fiber material,

ceramic fiber products' unique structural design features are one of the reasons why they have attracted much attention in many industrial applications. By deeply analyzing the structural design characteristics of ceramic fiber products, we can better understand their excellent performance under extreme conditions such as high temperature and corrosion resistance, as well as the reasons for their wide application in various industries.

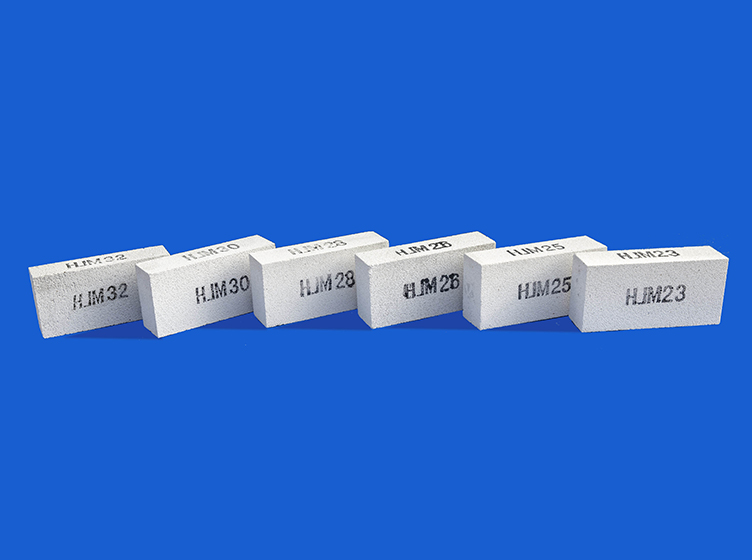

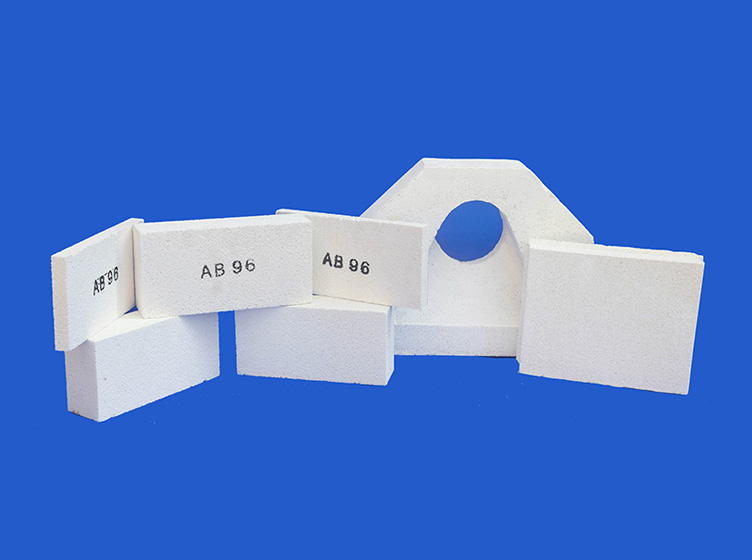

Fiber shape design

The basic structure of ceramic fiber products is composed of fiber shapes. This design enables the products to have excellent flexibility and tensile strength. These fibers are usually made of high-purity ceramic materials such as alumina and aluminum silicate. The microstructure of the fiber enables ceramic fiber products to maintain their shape integrity under high temperature conditions and are not prone to melting or deformation, ensuring that the product can be used for a long time in harsh environments.

Design of inorganic crystal structures

The inorganic crystal structure of ceramic fiber products is an important basis for their unique properties. Common ceramic materials, such as alumina and aluminum silicate, have good crystal structures, which give ceramic fiber products excellent physical and chemical properties. This structural design makes ceramic fiber products have excellent high temperature resistance, corrosion resistance, insulation and other properties, and are widely used in high-demand fields such as aerospace and chemical industry.

Insulation layer design

Ceramic fiber products are often designed as thermal insulation layers, with structures designed to minimize the conduction and loss of heat. This characteristic makes ceramic fiber products ideal thermal insulation materials and widely used in various high-temperature equipment. The design of the thermal insulation layer takes into account parameters such as thermal resistance and thermal conductivity to ensure reliable thermal insulation protection of the equipment in extremely high temperature environments.

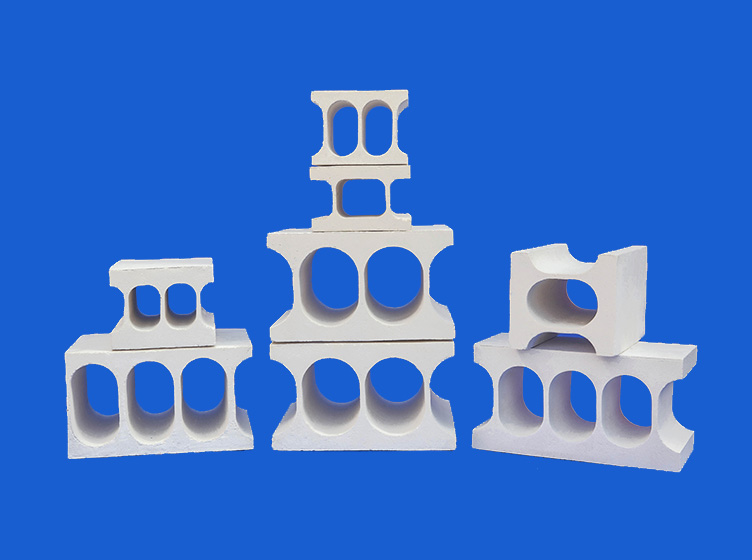

Intertwined design of fibers

In the structural design of ceramic fiber products, the fibers are usually intertwined. This design helps enhance the overall strength and toughness of the product. The intertwined fiber structure enables ceramic fiber products to better disperse and absorb energy when subjected to external impact or twisting force, improving the flexural strength of the product, making it more durable and reliable in industrial applications.

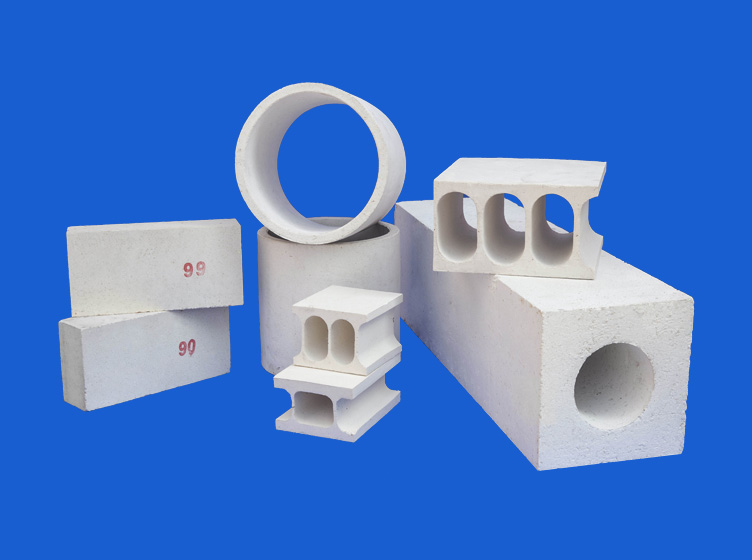

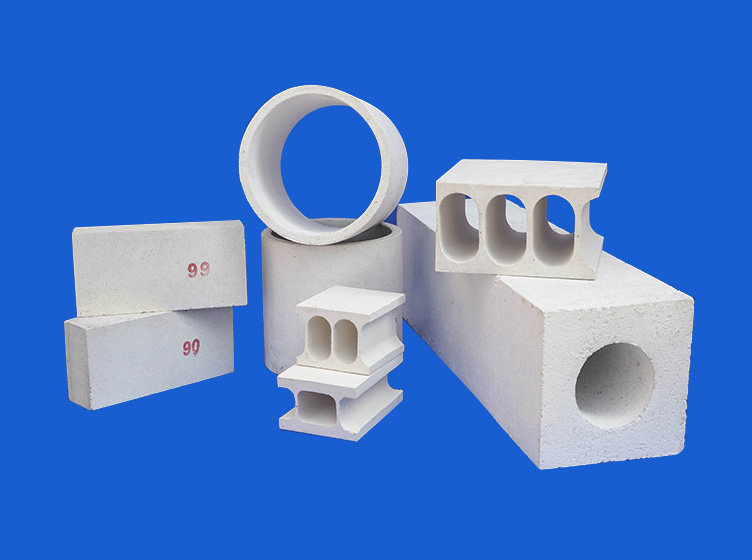

Multi-layer structure design

Some ceramic fiber products adopt multi-layer structure designs to meet different needs in different fields for thermal insulation, corrosion resistance and other properties. The multi-layer structure design enables ceramic fiber products to combine multiple properties such as light weight, high strength, and high temperature resistance in the same product, improving its applicability and flexibility.